In today’s dynamic marketplace, staying ahead of the curve is paramount for businesses across industries. This relentless pursuit of innovation extends to the very materials used in product development and manufacturing. In this context, PP spunbond nonwoven fabric emerges as a game-changer, offering a unique blend of versatility, sustainability, and cost-effectiveness.

Understanding Spunbond Nonwoven Fabric

Spunbond nonwoven fabric, also known as spunlaid nonwoven fabric, is a category of nonwoven textiles manufactured using a process called spunbonding. This technology involves extruding molten polypropylene (PP) – a thermoplastic polymer – into fine fibers. These fibers are then laid down onto a conveyor belt in a random formation and subsequently bonded together using heat, pressure, or chemical adhesives. The resulting fabric boasts a range of desirable properties, including:

1. High Strength and Durability: Spunbond nonwoven fabrics exhibit remarkable strength and tear resistance, making them ideal for applications demanding robustness.

2. Lightweight and Breathable: These fabrics are surprisingly lightweight and breathable, offering comfort and flexibility in various applications.

3. Water-resistant and Repellent: Spunbond fabrics possess inherent water-resistant properties, repelling liquids and making them suitable for applications requiring moisture protection.

4. Cost-effective and Recyclable: The manufacturing process of spunbond fabrics is efficient and cost-effective, translating to competitive pricing. Additionally, these fabrics are recyclable, contributing to environmental sustainability.

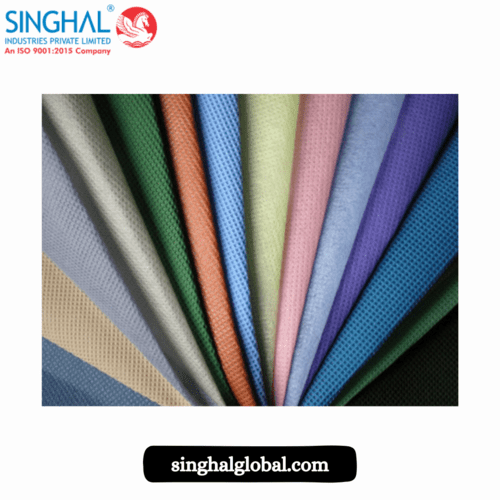

5. Versatility and Customization: Spunbond fabrics can be easily customized in terms of thickness, weight, and color, catering to diverse application needs.

Spunbond Nonwoven Fabric: Applications Across Industries

The unique properties of PP spunbond nonwoven fabric have propelled its adoption across a wide spectrum of industries. Here are some prominent examples:

1. Healthcare: Spunbond fabrics find extensive use in the healthcare sector as disposable medical gowns, drapes, caps, and wipes. Their inherent hygiene and barrier properties make them crucial for maintaining sterility in medical environments.

2. Hygiene and Sanitation: These fabrics are employed in the production of disposable diapers, wipes, and feminine hygiene products due to their absorbency, breathability, and comfort.

3. Agriculture: Spunbond fabrics are utilized in agriculture for crop covers, seed germination blankets, and weed control mats, promoting optimal growing conditions.

4. Construction: The construction industry leverages spunbond fabrics for roofing underlayment, waterproofing membranes, and insulation applications due to their strength and water-resistant properties.

5. Packaging: Spunbond fabrics are increasingly used in eco-friendly packaging solutions as reusable bags, pouches, and protective wraps, offering a sustainable alternative to traditional materials.

6. Apparels: Spunbond fabrics play a role in the production of disposable garments, shoe covers, and various apparel components, catering to specific needs in the apparel industry.

The Rise of Spunbond Nonwoven Fabric in India

India’s nonwoven fabric market is witnessing significant growth, driven by factors like rising disposable income, increasing hygiene awareness, and a burgeoning healthcare sector. Spunbond nonwoven fabrics, in particular, are experiencing a surge in demand due to their affordability, versatility, and suitability for various applications.

Finding Spunbond Nonwoven Fabric Manufacturers in India

In the bustling landscape of India’s textile industry, spunbond manufacturers hold a significant position, embodying innovation and quality. These manufacturers specialize in producing non-woven fabrics through the spunbonding process, which involves extruding filaments and bonding them together to form a cohesive material. India boasts a thriving market for spunbond products, catering to diverse sectors such as agriculture, healthcare, and packaging. With a focus on advanced technology and sustainable practices, Spunbond manufacturers in India are at the forefront of meeting global demand for reliable and eco-friendly non-woven solutions.

Conclusion

PP spunbond nonwoven fabric presents a powerful and versatile material solution for a vast array of industries. Its unique blend of strength, affordability, and sustainability makes it a compelling choice for businesses seeking innovative and eco-conscious material options. As the demand for nonwoven fabrics continues to rise in India and globally, PP spunbond nonwovens are poised to play an even more significant role in shaping the future of various sectors. By harnessing the power of this remarkable material, businesses can achieve greater efficiency, sustainability, and ultimately, success in today’s competitive marketplace.

FAQs (Frequently Asked Questions)

Q1. What are the advantages of using PP spunbond nonwoven fabric?

A1. Spunbond nonwoven fabrics offer a compelling combination of benefits, including high strength, lightweight construction, water resistance, cost-effectiveness, recyclability, and customizability.

Q2. What are some alternatives to PP spunbond nonwoven fabric?

A2. Woven fabrics, knitted fabrics, and other nonwoven materials like PET spunbond nonwovens can be considered alternatives, depending on the specific application requirements.

Q3. How can I ensure the quality of PP spunbond nonwoven fabric?

A3. Reputable spunbond non woven manufacturers will provide detailed specifications and certifications regarding the fabric’s properties like strength, weight, and breathability. It’s advisable to request samples and conduct your own testing to ensure the fabric meets your specific needs.