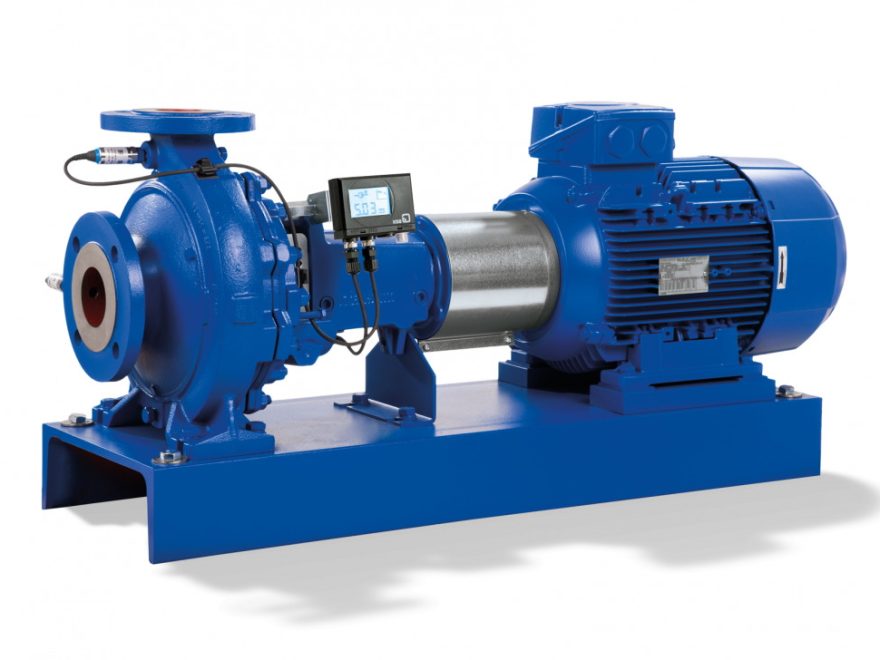

Canned motor pumps, also referred to as sealless pumps, are a type of centrifugal pump used widely across industries. Their lack of mechanical seals or couplings makes them highly reliable and efficient while pumping hazardous or toxic fluids without fear of contamination.

In this blog post, we’ll take a closer look at how canned motor pumps are utilized across various industries and applications.

Chemical Industry

The chemical industry is a major user of canned motor pumps. These units are ideal for transporting highly corrosive, acidic, or alkaline chemicals from one location to another without the risk of leakage – an essential step when handling hazardous substances.

Furthermore, canned motor pumps have the capacity to withstand extreme temperatures and pressures, making them perfect for this application.

Pharmaceutical Industry

The pharmaceutical industry is a major user of canned motor pumps. These units transport highly sensitive and expensive fluids like vaccines and drugs with any contamination risk being catastrophic.

Canned motor pumps also play an integral role in processing medicines and drugs that require high levels of cleanliness and hygiene – something essential in the pharmaceutical industry.

With their sealless design, these pumps guarantee zero contamination risk – essential for those working within it.

Nuclear Industry

The nuclear industry demands high safety and dependability standards. Canned motor pumps are widely used for handling radioactive materials due to their complete leak-proof design that eliminates any risk of contamination.

These pumps cool and transfer nuclear fuel while maintaining water levels inside reactors; their sealless design guarantees no risk of radioactive materials leaking into the environment, making them essential components in nuclear power plants.

Other Post You May Be Interested In

- Slot Inces: Link Situs Slot Gacor Starlight Princess 1000 Mudah Menang

- Slot Deposit 25 Bonus 25 Hari Ini Menang Hadiah Menarik

- naturecan-clas-capsules-90-caps

- Jelajahi Dunia Slot SixSixSiX Hacksaw: Temukan Favorit Anda Hari Ini!

- Koi Gate: Daftar dan Mainkan Tembak Ikan Seru Hari Ini

- Euro Cup Slot > Slot FUNKY GAMES Terbaru 2024

- Slot Pulsa: Situs Slot Pulsa Aman & Terpercaya

- Facebook Constantly Receives Investing News Headlines

- How To show Google Discovery Better Than Anyone Else

- Daftar Situs Terbaik: Bandar Judi Bola Mix Parlay yang Aman di 2024

- Choosing a Professional Financial Advisor

- Consequences of Self-Plagiarism While Writing a Dissertation

- LinkedIn Image Ad Specs: A Complete Guide| Digital Solutions Waqas

- Land Sale In Lahore For Farm Houses

- How Construction Industry Can Gain Benefits from Mobile Apps

- Living Room Curtains are an Essential Component of Interior Design

- Get a Thrilling Experience with Atlantis Water Park Dubai Tickets 2023

- Discover the Future of Art, Science, and Technology with Museum of the Future Tickets 2023

- Movers London

- World’s most expensive wedding cakes

- How a Child’s Brain Works at Indoor Car Track Racing

- Indoor Rock Climbing for Kids: Non Stop Fun & Learning

- Powerful Technology

- Hair Transplant In Lahore Cost Can Shock You In Terms Of Its Quality

- The Art of 3D Product Rendering: Bringing Your Products to Life

- Aditya Roy Kapur Age, Height, Net Worth, Wife, Family, Career & Bio

- Stevia Powder: The Best Sugar Substitute

- You Need to Know Before Requesting a Car Shipping Quote

- How to Draw A Volcano Easily

- Common issues faced when deleting a POF account and how to resolve them

- Artificial intelligence and machine learning to drive hyperautomation market

- The Benefits of Seeking Help from a Licensed Professional Counselor

- Blue World City: An Overview of Pakistan’s Upcoming Mega Project

- Top 5 Will Writing Services in Bristol: Which One is Right for You?

- What Is A Major Service? Why Is It Critical For Your Vehicle?

- What happens if you think that something went wrong outlook?

- The Power of BusinessReviewIt

- Bizlistee: Connecting Businesses to Customers

- Location of the HP Printer Ink Cartridge Secret Reset Button

- Learn the True Essence of Driving Under the Right Supervision

- Dissertation Services – Advantages and Disadvantages

- Here’s A Detailed Report on Consequences of a Worn Head Gasket

- Working Smarter, Not Harder: Boost Your Productivity

- Maximizing Natural Light in Home Decor

- Blue World City – The Upcoming Marvel of Islamabad

- Finding The Perfect Knife For Every Situation

- Slice And Dice – Find The Perfect Knife At This Store

- Indulge in the Richness of Types of Red Velvet Cakes Perfect for Birthday Celebrations

- The Top Benefits of Choosing a Local Transfer Service for Your Next Trip

- Unlocking The Secrets Of Damascus Steel Pocket Knives

- Web Design Agency vs. Freelance Web Designer: Which is Right for Your Dubai Business

- Unlock Your Inner Master Chef With A Damascus Steel Chef Knife

- Discover The Comfort Of The Fear Of God Essentials Tracksuit!

- How Plants Are Beneficial For Your Health?

- How To Get More Instagram Followers For Brand Enhancement?

- The Grey Essentials Hoodie: A Must-Have for Your Wardrobe

- The Essentials Jacket: A Must-Have for Every Wardrobe

- The Essential Hoodie: A Must-Have Item for Your Wardrobe

- The Essential Sweatsuit: Comfort and Style Combined

- Essential Hoodie: Why You Need One in Your Wardrobe

- Essential Shirts: A Must-Have in Your Wardrobe

- Major Benefits Provided By Dental Ortho Treatment

- Learn Scuba Diving in Cartagena: Discover the Beauty of the Underwater World

- Yolo Watch Fortuner in Pakistan | Bluetooth Calling Smart Watch

- Experience True Opulence: Top Most Expensive Villas for Sale in Dubai

- Perks of Renting a Property in Dubai for Expats

- Build A Strong Support System And Seek Help When Needed

- Benefits of Wearing Men’s Tracksuits for Workouts and Outdoor Activities

- Achieving Snowflake SnowPro-Core Certification: Braindumps4it Exam Tips and Tricks

- The Cleveland Guardians: A Storied Baseball Legacy

- Importance of Writing in Today’s World

- Expand Your Business Globally with International B2B Marketplaces

- The Future Of Affiliate Marketing – Trends To Watch In 2023

- Let’s Maintain Product Importance with Custom Boxes

- The Booming Meal Kit Market: Trends, Challenges, and Opportunities | Renub Research

- What to consider when undergoing cosmetic treatment?

- Global Fruits Market To Be Driven By The Rising Demand For Variety Of Fruits In The Forecast Period Of 2023-2028 | EMR Inc.

- A Case Study on How a School Improved its Performance with Help of a School Management System.

- Best Cities for Property Investment in Pakistan: A Comprehensive Guide

- Global Automotive Switches Market To Be Driven By The Increasing Use Of Electronics In Automobiles In The Forecast Period Of 2023-2028 EMR Inc

- The Cherimoya Diet Has Many Health Benefits

- Hire the Best Assignment Helpers in the USA

- How to Cleanup Your QuickBooks Customer and Vendor Lists

- The Sweet Science Of Cookie-Making

- Have A Lavish Wedding With the Help of a Personal Loan

- Global Ultra-High Molecular Weight Polyethylene Market To Be Driven By Growing Demand From Various Applications In The Forecast Period Of 2023-2028 | EMR Inc.

- How Real Estate Appraisers Determine Property Values?

- Five Reasons Your Business Needs a GPU Cloud Server.

- Hormone Replacement Therapy Market will be around US$ 26.80 Billion by 2027

- Cheap VAT Registration And Audit in UAE

- Buy Google 5 Star Reviews

- The Benefits Of Reading For Mental Health And Wellness

- Global Plastic Pallets Market To Be Driven By Increased Demand From End Use Industries In The Forecast Period Of 2023-2028 | EMR Inc.

- Clothes Wholesale UK: The Benefits of Buying in Bulk

- The Perfect Blend of Comfortable and Fashionable Sweatshirt

- Global Medical Bed Market To Be Driven By The Growing Prevalence Of Health-Related Issues In The Forecast Period Of 2023-2028

- Writing an assignment on a tight deadline | Tips and tricks

- 5 Surprising Benefits of Getting Python Assignment Help Services

- A Beginner’s Guide To Understanding Vape Tanks

- The Future of Healthcare: How Analytics is Shaping the Industry

- Benefits and Drawbacks of Red Onion

- Mind-blowing Gifts that Girls will fall in love

- How to Draw Doorway Drawing

- How to Live a Wholesome Life?

- The Hands-Down Best Concepts of Financial Metrics by Assignment Help Experts

- Differences between Master’s And Undergraduate Dissertations

- Here’s What Can Go Wrong With Your Car’s Radiator?

- Discover The Benefits Of Pixel Backgrounds With Tech Rags.com

- Free Duck Coloring Pages | Kids Coloring Pages

- Cardiac Arrest Treatment

- Outlook Customer Service Number +1-833-859-2989

- Top-Rated Plumbing Services in Dubai: Hire a Reliable Plumber Today

- The Benefits Of Hosting Events In The Metaverse

- The Ultimate Guide to Getting the Best Car Shipping Quote

- The Best Warm Throw Blankets Will Keep You Warm and Fashionable

- Alcohol Testing of Employees: What You Need to Know About Alcohol Testing Services

- German Public Universities: A Comprehensive Guide for International Students-Study Abroad

- Here Are Major Mechanical Failures That Turn Out To Be Fatal On The Road

- What Happens When Your Car’s Tank Is Filled With Wrong Type of Fuel – Explained!

- Global Human Enhancement Market Price, Share, Scope, Outlook, Report and Forecast Period Of 2023-2028

- Top reason to buy Instagram followers from our services

- The Quickest & Easiest Way To Buy Pinterest Likes

- dissertation writing Is Bound To Make An Impact In Your Business

- Introduction to Service Mapping in ServiceNow

- Online passport Seva portal in India

- During enrolment, government agencies sign up through the online marketplace.

- FSSAI Food Permit Enlistment for Flipkart Dealers

- Why Buy Instagram Likes in Australia: Benefits and Advantages

- Ensuring Legality and Enforceability of E-Digital Signatures

- Global EClinical Solutions Market Price, Share, Scope, Outlook, Report and Forecast Period Of 2023-2028

- Discover the Ultimate Selection of Truck Accessories – New and Used – All in One Place

- 10 Tips for Building an Effective Teacher Email List for Email Marketing

- Hormone Replacement Therapy Market will be around US$ 26.80 Billion by 2027, driven by Increasing Awareness of Postmenopausal Issues among Women

- Top Reasons to Invest in Professional Mold Inspection Services

- UNESCO World Heritage Sites of Nepal

- Beware of these 5 common traps when hiring a Movers!

- Blackberries Are Important for Men’s Health

- Taking Care Of Your Kidneys As A Man

- Future-Proof Your React Native Development with These Proven Tips and Tricks!

- How to clean your old house before moving out

- Walkways Made Safe and Beautiful Again: Sidewalk Repair NYC

- The Benefits of Economics Assignment Help for Busy Students

- Compare Electricity Rates

- How to Join the NGO Sector

- Find the Best Personal Trainer in Jersey City with These Tips

- How to Manage Stress for Better Health

- Maximize Your Potential with the Best Academic Services in 2023

- Moving With Pets, The Ultimate Guide

- Black Pepper Has a Wide Range of Men’s Health Benefits

- Marketing to Doctors – A Proven Lead Generation & Sales

- A Comprehensive Guide to Financial Due Diligence Services: What You Need to Know

- Student Loan Policy Can Make Your Student Life Easier

- Red Rice Is Good For Your Body

- Tips and Tricks for Getting Approved for a Car Loan with Bad Credit

- Take Action To Prevent Asthma Attacks

- What exactly is meant by “Open AI Chat GPT 3”?

Oil and Gas Industry

The oil and gas industry is a major user of canned motor pumps. These devices transport crude oil, refined petroleum products, and natural gas from one location to another.

Furthermore, these pumps are employed in processing and refining oil and gas where high levels of safety and dependability must be guaranteed.

Their sealless design prevents any risk of leakage or contamination, making them essential components of oil pipelines.

Water Treatment Industry

The water treatment industry is a major user of canned motor pumps.

These units are employed for transferring and treating water and wastewater, where high standards of hygiene and safety must be maintained.

Canned motor pumps also transport chemicals and other fluids used in water treatment processes where any leakage or contamination could prove hazardous.

Thankfully, their sealless design eliminates that risk, making them essential components in water treatment plants.

Canned Motor Pumps Offer Several Advantages

Canned motor pumps have several advantages over conventional pumps that require mechanical seals or couplings.

Some key benefits of canned motor pumps include:

- Canned motor pumps are 100% leak-proof, eliminating the risk of contamination or pollution.

- Maintenance-Free: Canned motor pumps do not need any upkeep or servicing since they lack mechanical seals or couplings that need replacing or repair.

- Energy Efficient: Canned motor pumps are highly energy-efficient, as they do not experience frictional losses associated with mechanical seals or couplings.

- Cost-Effective: Canned motor pumps are cost-effective due to their long lifespan and lack of maintenance requirements, such as changing mechanical seals or couplings.

- Canned motor pumps are safe and dependable, as they are built to withstand extreme conditions like high temperatures, pressures, and corrosives.

- This makes them the ideal choice for industries requiring high levels of safety and dependability such as nuclear plants, chemical plants, and pharmaceutical firms.

- Environmentally Friendly: Canned motor pumps are environmentally friendly, as they do not leak any fluids or gases into the environment.

This reduces pollution risks and helps safeguard our planet

Canned motor pumps are an integral part of various industries, such as chemical, pharmaceutical, nuclear, oil and gas, and water treatment.

Compared to traditional pumps they offer several advantages including leak proofing, maintenance-free operation, energy efficiency cost-effectiveness safety reliability environmental friendliness.

If you require a pump that can safely handle hazardous or toxic liquids without the risk of leakage or contamination then Fnengg Provide canned motor pumps manufacturer is your ideal choice for you.