In contemporary business landscape, strength efficiency is a pinnacle precedence for organizations throughout the globe. As the value of power continues to upward push and the pressure to lessen carbon footprints intensifies, corporations are constantly seeking modern methods to optimize their strength utilization. One key era that would significantly enhance electricity performance is the plate fin warmth exchanger. This incredibly efficient heat transfer tool is gaining popularity for its capability to conserve electricity, decrease working expenses, and decorate system performance.

But is the plate fin warmness exchanger the missing link to your strength method? In this weblog, we’ll discover the role of this device, its blessings, and the way it suits into a broader electricity-saving plan, probably working alongside complementary technology like Nash vacuum pumps.

What is a Plate Fin Heat Exchanger?

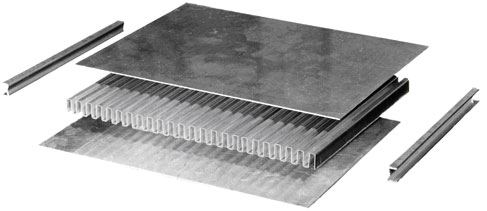

A plate fin heat exchanger is a compact heat switch device that consists of plates and fins stacked collectively to maximise surface area and improve warmth transfer among fluids. The plates are typically crafted from materials with top notch thermal conductivity, inclusive of aluminum or stainless steel. The fins, inserted between the plates, in addition growth the heat transfer vicinity, taking into consideration exceptionally efficient thermal trade.

This generation is extensively utilized in industries like aerospace, automobile, chemical processing, and strength generation, wherein strength efficiency is crucial. The compact design of the plate fin warmth exchanger lets in it to handle excessive warmth loads with out taking on lots area, making it perfect for packages wherein space is limited however efficiency is a priority.

How Does a Plate Fin Heat Exchanger Work?

At its middle, the plate fin warmness exchanger works by way of shifting warmness among fluid streams which might be kept separate. One fluid flows through the channels among the plates, at the same time as the other flows between the fins. As the fluids skip thru the exchanger, heat is transferred from the hotter fluid to the cooler one, thanks to the conductive properties of the plates and fins.

The fins play a critical position in this process with the aid of improving the surface place for heat switch, permitting greater green strength change. This design is mainly useful for applications requiring excessive heat transfer prices, which include cooling systems or waste heat healing gadgets.

Benefits of a Plate Fin Heat Exchanger

1. Enhanced Energy Efficiency

The number one gain of a plate fin warmth exchanger is its potential to seriously enhance power efficiency. By shifting heat extra efficiently among fluid streams, it reduces the amount of power had to attain the preferred thermal output. This can lead to good sized strength savings, specifically in huge-scale business programs.

In industries where energy consumption is a major operational value, putting in a plate fin warmness exchanger can help decrease strength payments and reduce the overall environmental impact. This makes it an essential aspect in an power-saving approach.

2. Compact and Space-Efficient Design

The plate fin warmth exchanger is thought for its compact length and lightweight production, making it an excellent choice for industries wherein space is a proscribing component. Despite its small footprint, it gives high-performance warmness switch talents, which means it could be without problems included into existing structures without requiring foremost adjustments.

This area performance also makes it perfect for mobile applications, including in aerospace and automotive industries, where minimizing weight and area is vital to performance.

3. Customizable for Various Applications

One of the most appealing features of the plate fin heat exchanger is its versatility. It can be custom designed to in shape different heat transfer wishes, making it suitable for a wide variety of applications. Whether your machine requires cooling, heating, or recuperating waste warmth, this sort of warmness exchanger can be designed to satisfy unique operational requirements.

Industries together with chemical processing, refrigeration, and power era rely closely on these exchangers due to the fact they can be tailored to match the particular thermal needs of every procedure.

4. Durability and Long Lifespan

Another advantage of the plate fin heat exchanger is its durability. Made from awesome substances like aluminum or stainless steel, these exchangers are constructed to withstand harsh running conditions, including excessive stress and temperature variations. This durability ensures a longer lifespan compared to other types of warmth exchangers, lowering the want for common replacements and renovation.

By incorporating a dependable plate fin warmth exchanger into your strength strategy, you no longer simplest optimize electricity use but also reduce downtime and preservation costs.

5. Low Maintenance

Thanks to its easy and robust layout, the plate fin heat exchanger calls for minimal renovation. The materials utilized in its construction are proof against corrosion, fouling, and other put on and tear that can plague other heat exchangers. This low-protection element makes it a value-powerful solution for industries that can not have enough money extended shutdowns or costly maintenance.

Could a Plate Fin Heat Exchanger Fit Your Energy Strategy?

Now that we’ve explored the blessings of a plate fin heat exchanger, the subsequent question is whether it is able to be the missing hyperlink for your electricity approach. The answer largely relies upon for your precise electricity dreams, the nature of your operations, and the performance of your current structures.

1. Reducing Energy Costs

If reducing energy charges is a number one purpose to your business, then a plate fin warmth exchanger could be an invaluable addition for your system. By enhancing the efficiency of warmth transfer methods, those exchangers lower the overall electricity required to achieve the equal output. Whether you’re looking to cut costs in heating, cooling, or method optimization, the enhanced efficiency furnished via this era can make a contribution to long-term financial savings.

2. Improving Waste Heat Recovery

Many industries produce a big quantity of waste warmth that is frequently misplaced. A plate fin warmth exchanger can help recover and reuse this power, turning waste into a treasured useful resource. By capturing and redirecting waste heat, you can reduce the call for for brand spanking new strength inputs, in addition lowering your operational prices and minimizing environmental effect.

3. Integrating with Existing Systems

Another motive a plate fin warmth exchanger may be the lacking hyperlink on your energy method is its ability to combine seamlessly with existing structures. If you already use Nash vacuum pumps or different gadget that calls for warmness management, the addition of a plate fin heat exchanger can enhance the general efficiency of your operations. This combination can optimize each vacuum technology and thermal law, main to stepped forward performance across the board.

4. Sustainability Goals

For businesses centered on sustainability, lowering electricity intake is a top precedence. The plate fin warmness exchanger aligns flawlessly with these dreams via maximizing energy efficiency and minimizing waste. By making an investment in this technology, you not most effective cut down on power fees but additionally contribute to a greener future via decreasing your carbon footprint.

Conclusion

In an era in which power efficiency is greater critical than ever, the plate fin warmth exchanger stands out as a flexible and green answer for optimizing warmness transfer. Its compact layout, durability, and strength-saving abilities make it a powerful tool in accomplishing your power approach dreams. Whether you’re trying to lessen operational costs, enhance waste warmness recovery, or enhance the efficiency of structures regarding Nash vacuum pumps, the plate fin warmness exchanger should indeed be the missing hyperlink.

By incorporating this era into your operations, you may liberate good sized energy savings, reduce environmental effect, and function your business for lengthy-time period achievement in a global that increasingly values sustainability and efficiency.